RoHS Vitreous Enamel Coated Wirewound Resistors (KNP-VE/LF)

Wirewound Resistors (KNP-VE/LF) Introduction

RoHS Vitreous Enamel Coated Wirewound Resistors (KNP-VE/LF) Boost High Energy.

The KNP-VE/LF Series of vitreous enamel coated power resistors from Direct offers a cost-competitive alternative over the 1W-30W power range. The range is available with resistance values of 0.1Ω to 47KΩ in working voltage of 75V to 1000V, and with body sizes that match the industry standards.

Vitreous enamelled resistors were introduced at a time when alternative directly applied coatings could not withstand the thermal stresses caused by the resistors' high body temperatures.

Token offers the durability of a lead free conformal vitreous enamel coating, permits the KNP-VE/LF Series resistors to maintain a hard coating while operating at high temperatures. Mechanical integrity is enhanced by the all-welded construction.

Power KNP-VE/LF Wirewound Series are ideal for computer, communications and industrial applications in which cost, quality, and reliability are key considerations. The KNP-VE/LF series is RoHS compliant and Ayrton Perry noninductive windings are available on request.

To address your need for technical and economic success in a timely manner, our custom solutions are the best choice. Contact us with your specific needs.

Download complete PDF RoHS Wirewound Vitreous Enamel Resistors (KNP-VE/LF).

- Welders, High voltage applications.

- Power tools, Consumer applications, Power supplies.

- High-switching applications, Home entertainment, appliances.

- Excellent pulse load capability, Axial leads, All-welded construction

- Power ratings 1W to 30W, Resistance range 0.1Ω to 47KΩ, Tolerance ±2%, ±5%

- Products with Pb-free Terminations and RoHS compliant, rugged vitreous enamel coating withstands high humidity and temperature cycling

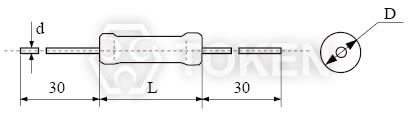

(KNP-VE/LF) Specifications & Dimensions

RoHS High Energy Wirewound Resistor |

||||||||||

| Type | 70°C Wattage (W) |

25°C Wattage (W) |

Resistance (Ω) | Working Voltage (V) | Temperature Coefficient (PPM/°C) |

Surface Temperature (°C) |

Dimensions (mm) | |||

| J (±5%) | G (±2%) | L Max. | D ±1 | d ±0.2 | ||||||

| KNP-VE/LF | 0.5 | 1 | 0.1 ~ 510 | 1 ~ 300 | 75 | ≤ 250 | ≤ 450°C | 10 | 3.5±1 | 0.8 |

| 1 | 2 | 0.1 ~ 1K | 1 ~ 680 | 100 | 12 | 4.5±1 | 0.8 | |||

| 2.6 | 3 | 0.1 ~ 5K1 | 1 ~ 1K5 | 120 | 12.7 | 5.6±1 | 0.8 | |||

| 4.5 | 5 | 0.1 ~ 10K | 1 ~ 6K8 | 300 | 22 | 7±1 | 0.8 | |||

| 6 | 7 | 0.1 ~ 12K | 1 ~ 8K2 | 350 | 24 | 7.4±1 | 0.8 | |||

| 7 | 8 | 0.5 ~ 20K | 1 ~ 15K | 500 | 33 | 8±1 | 0.8 | |||

| 9.5 | 11 | 0.5 ~ 27K | 1 ~ 20K | 650 | 38.1 | 8±1 | 1 | |||

| 15 | 18 | 0.5 ~ 36K | 1 ~ 24K | 700 | 45.8 | 9.5±1 | 1 | |||

| 20 | 23 | 1 ~ 51K | 10 ~ 39K | 800 | 54 | 9±1 | 1 | |||

| 25.8 | 30 | 0.5 ~ 47K | 1 ~ 36K | 1000 | 64 | 12±1 | 1 | |||

(KNP-VE/LF) Performance

| Test Item | Characteristics | Test Methods: SJ1330-78 |

| Solderability | Free flow of solder | 235±5°C, 2s Groove welding |

| Terminal strength | ΔR ≤ ± (1%R+0.05Ω) | ≤4.3W 10N, ≥6W 20N |

| Overloading | ΔR ≤ ± (1%R+0.05Ω) | θ A=-55°C θ B=+200°C, 5 Cycles |

| Temperature Change | ΔR ≤ ± (1%R+0.05Ω) | 235±5°C, 2s Groove welding |

| Collision Test | ΔR ≤ ± (1%R+0.05Ω) | Acceleration 390m/s2, 4000 times |

| Impact Test | ΔR ≤ ± (1%R+0.05Ω) | Acceleration 490m/s2, 11ms, 18 times |

| Vibration Test | ΔR ≤ ± (1%R+0.05Ω) | Frequency 10-500Hz, Acceleration 98m/s2, 6h |

| Temperature Rise | ≤245°C | Apply rated power Load |

| Constant Damp Heat | ΔR ≤ ± (5%R+0.05Ω) | Temperature 40±2°C, Temperature 93+2/-3%, 56h |

| Room temperature Durability | ΔR ≤ ± (5%R+0.05Ω) | Rated power load at room temperature 1000h |

(KNP-VE/LF) Wirewound High Power Resistors - Order Code

| KNP-VE | - | 11W | 10R | J | P | ||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||